Capabilities

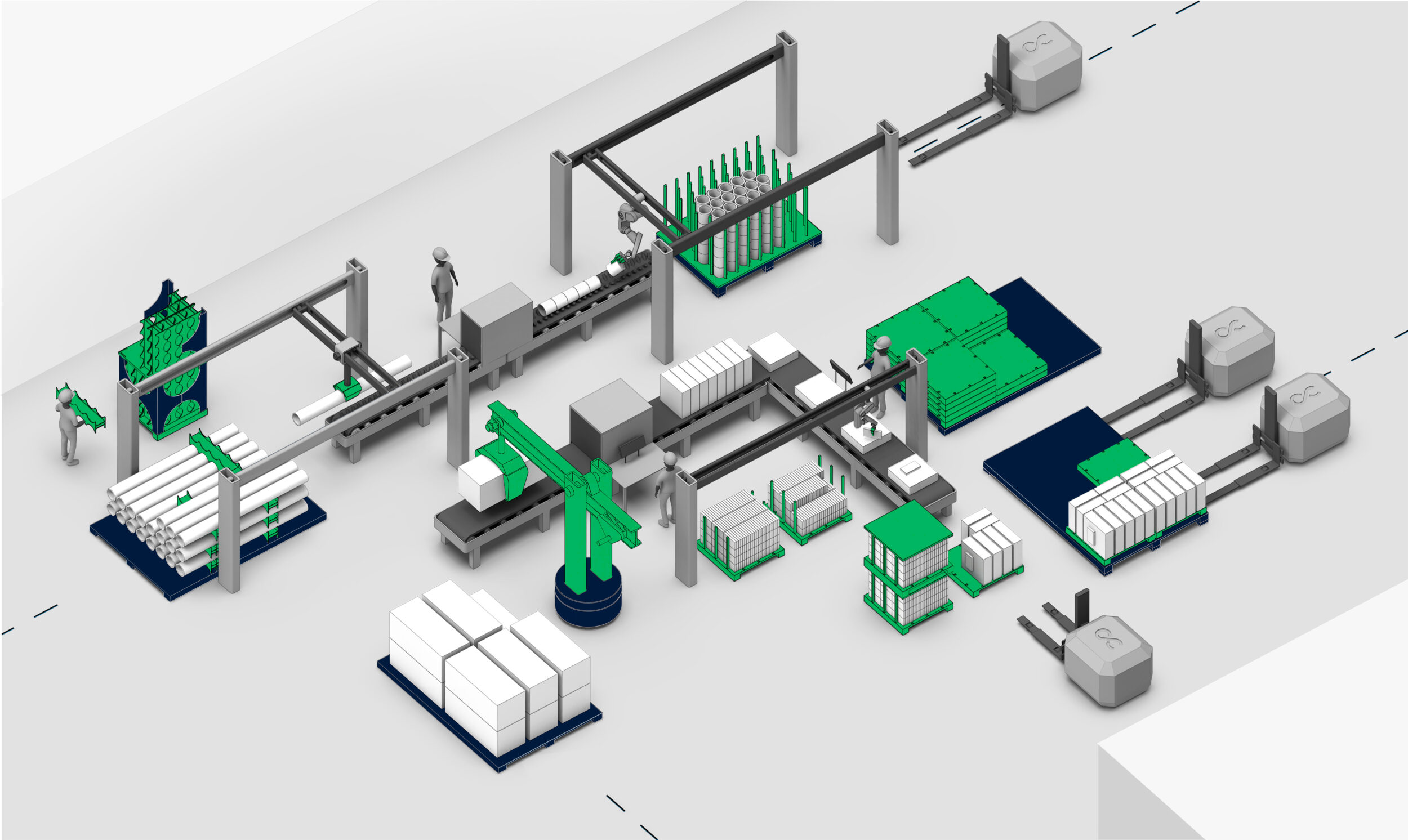

Tailored service solution designed for your industrial needs

OUR SERVICE MODELS

Striving towards a stategic partnership

We are a partner in industrial production development, designing and implementing necessary solutions for various challenges and development needs in production.

Design: We develop innovative concepts for new machines, equipment, tools, and process stages tailored to meet your specific needs and goals.

Production & Delivery: With our subcontractor network, we manufacture, assemble, test, and deliver all of our designs.

Partnership

With our Partnership Model, we emphasize seamless collaboration and being a strategic ally in achieving operational excellence. This flexible model enables smooth cooperation even with large volumes, eliminating unnecessary administrative work.

Project delivery

The Project Delivery Model provides you with a targeted solution tailored to your specific needs. From concept to implementation, we meticulously design and execute the project, ensuring seamless integration into your operations. Our emphasis is not solely on delivering a product but on providing a comprehensive solution that enhances your production capabilities and elevates your industry presence..

Why Creo Tools?

Drive Efficiency

Scale with Confidence

Streamline Operations

Prioritize Safety

Process

How we work

01

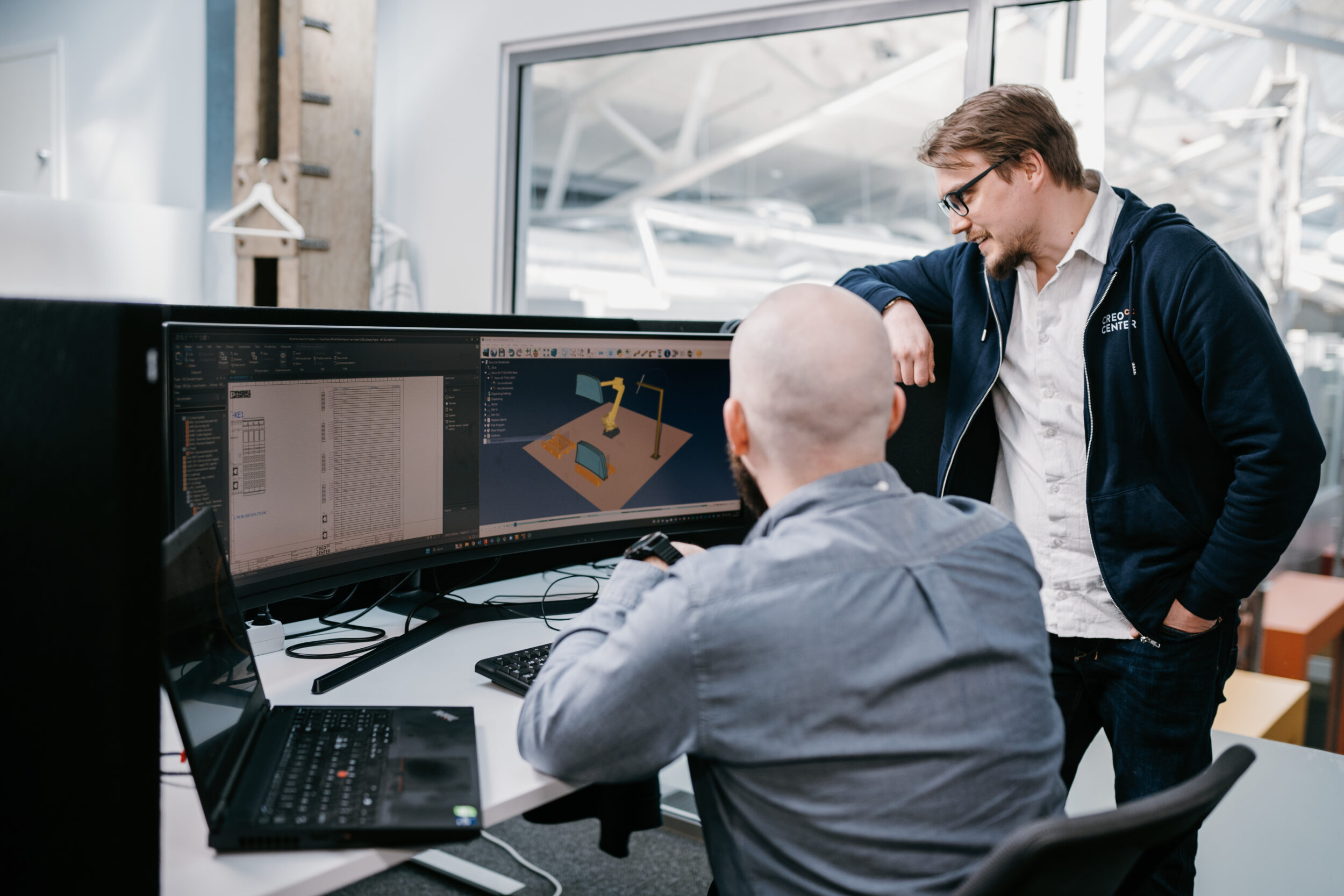

Design

Our collaboration begins with an in-depth understanding of your needs, often conducted through on-site visit to your production facilities. The visit provides the opportunity to deliver a detailed quote on the conceptual design. Through close collaboration with our and your experts, we engage in innovative conceptualization to tailor pioneering solutions. These solutions are designed to meet your specific needs, ensuring a tailored approach that adeptly addresses your unique challenges.

02

Production

After reaching consensus on the concept, our focus turns to translating refined design concepts into concrete form. Through close collaboration, we ensure that detailed manufacturing documentation accurately mirrors design specifications. Leveraging the expertise and facilities of specialized subcontractors, we guarantee a seamless transition from design to production, resulting in high quality, tailor-made equipment.

03

Delivery

At last, we ensure a seamless implementation of your project. Our team conducts on-site installations, ensuring the equipment seamlessly integrates into your operational environment. Following the installation, we conduct Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) to thoroughly validate the functionality and performance of the installed equipment. Our after-sales service offers ongoing support, maximizing the lifespan and efficiency of your equipment.

Creating intelligent production environments to drive innovation in technology. ”

Contacts

Contact Us

Required fields are marked with an asterisk (*). By submitting the form, I acknowledge that my information may be stored and used in the manner indicated in the privacy policy.